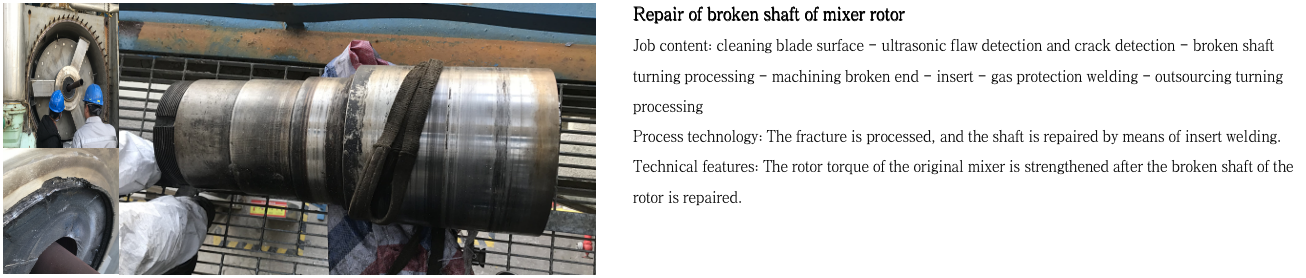

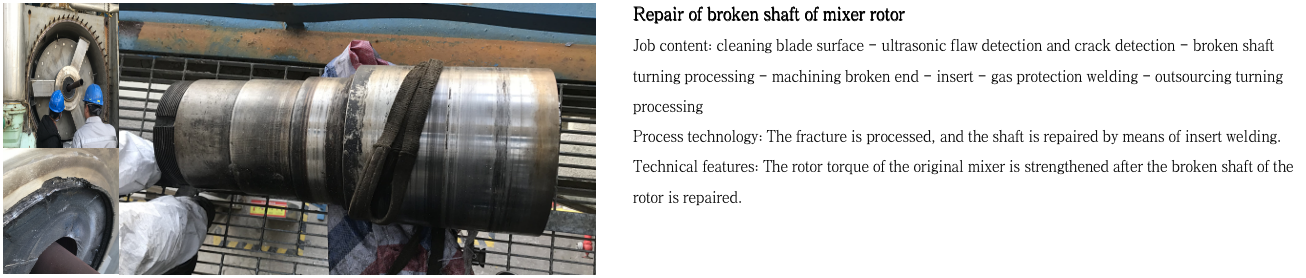

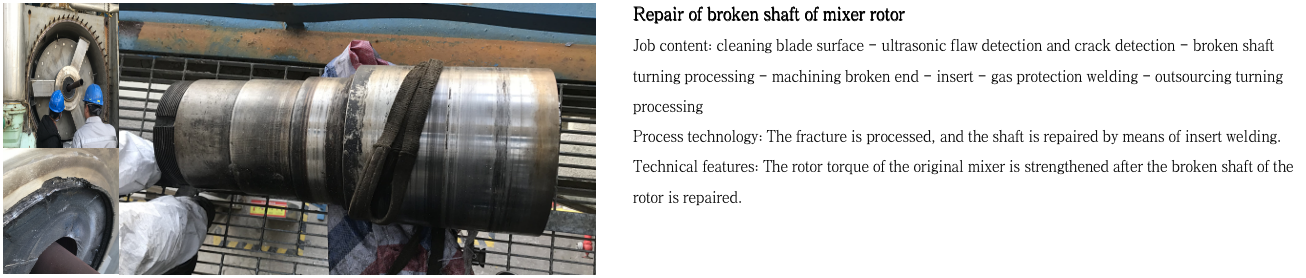

Apply laser flexible additive

remanufacturing technology to repair a broken shaft of mixer rotor

Apply thermal spray surface strengthening

remanufacturing technology to repair a turbine model ring

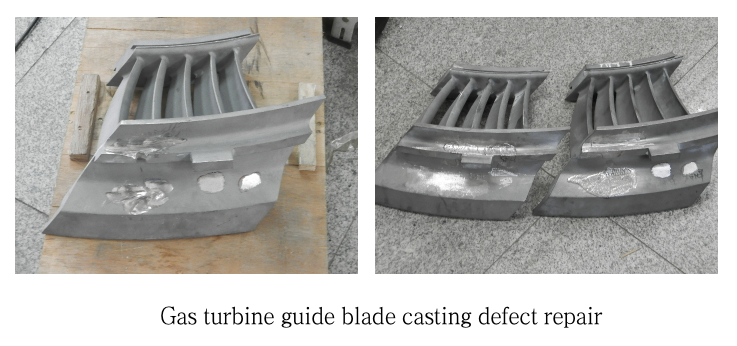

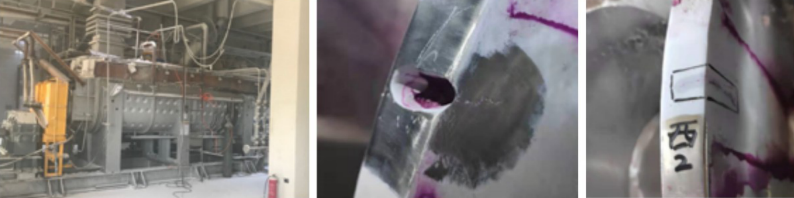

Apply high-energy pulse precision cold

welding surface strengthening remanufacturing technology to repair a gas turbine guide blade

casting defect

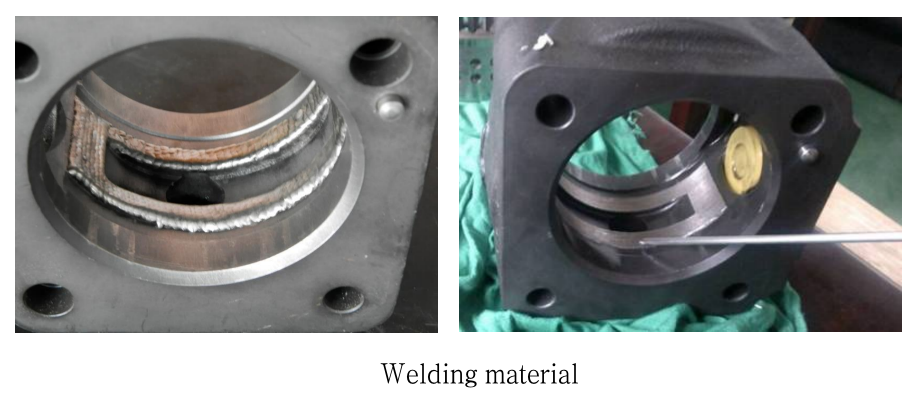

Apply micro-arc spark surface strengthening

remanufacturing technology to repair a welding material

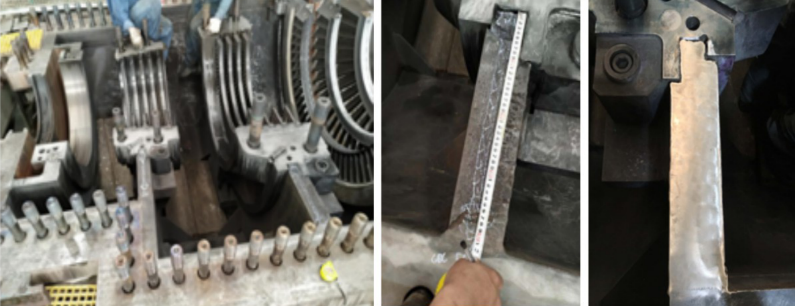

We provided an on-site technical service of

repair a PTA dry confidential cover

Job Description:

(1) Clean the worn place before surfacing; (2) Precision pulse

micro-surfacing: nickel/cobalt alloy with higher wear resistance

than the matrix and excellent weldability is selected as the

surfacing material at the worn part, and the worn part is surfacing

by the precision pulse micro-surfacing machine. (3) Pre-processing

of surfacing layer: electric or pneumatic grinding tools are used to

pre-process the surfacing layer; (4) Finishing: the repaired surface

is finished by using whetstone and sandpaper of different

granularity to meet the requirements of sealing surface size and

accuracy.

Process technology: High energy pulse cold welding additive

manufacturing

Technical features: the substrate has been maintained at a low

temperature and no deformation during the surfacing process; The

resulting surfacing layer has a metallurgical combination with the

matrix and high strength. The surfacing material used has higher

wear resistance than the matrix, higher efficiency and lower cost.

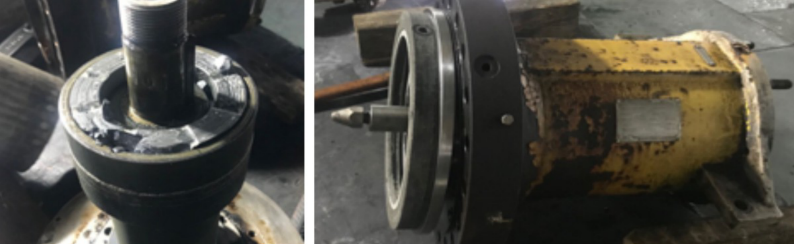

We solved a case of vacuum pump rotor

remanufacturing

We solved a case of conveyor roller

remanufacturing

We solved a case of PM2 pulping multi-disc

concentrator seal position remanufacturing

We solved a case of fan shaft

remanufacturing

We solved a case of combustion-driven blades

remanufacturing

We solved a case of double screw pump long

shaft bearing position remanufacturing

We solved a case of turbine bearing position

and machine seal repair

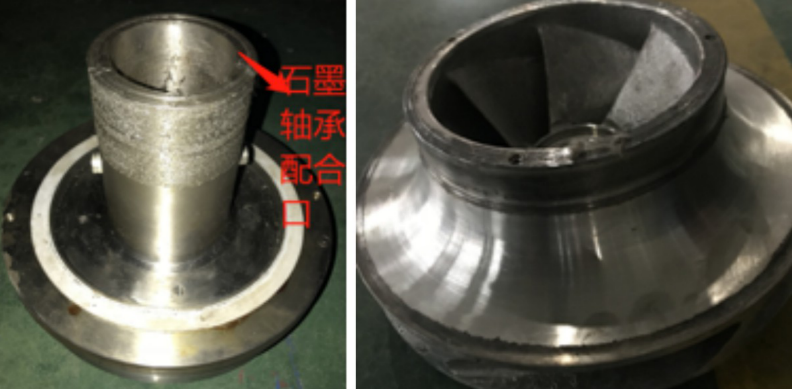

We solved a case of magnetic pump

remanufacturing

We solved a case of housing

remanufacturing

We solved a case of agitator rotor

repair

We solved a case of machining keyway

machining errors repair

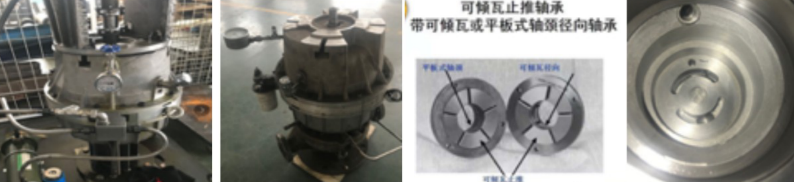

We solved a case of polymerization kettle

stirring spindle repair

We solved a case of roots blower shaft

repair

We solved a case of air compressor expansion

model ring spray repair

We solved a case of induced fan rotor

repair

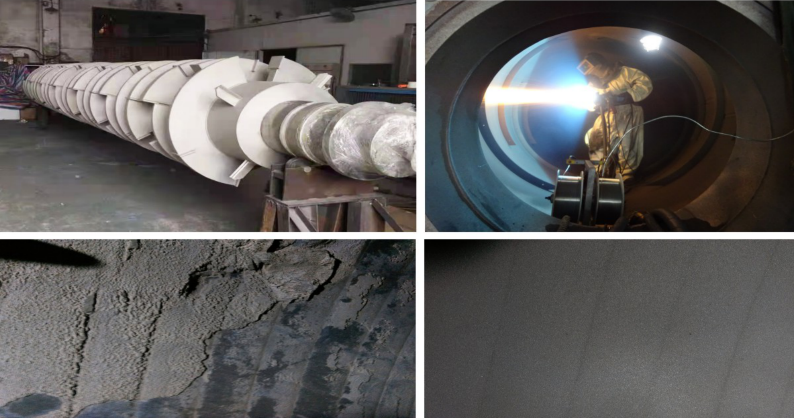

We solved a case of expansion dryer

repair

We solved a case of anti-pump rotor sealing

repair

We provided an on-site technical service of

RPF rotary valve rotor seal position

We provided an on-site technical service of

agitator rotor

We provided an on-site technical service of

heat exchanger head sealing ribs

We solved a case of sealing surface of the

discharge end of the dryer repair

We solved a case of loop repair

We provided an on-site technical service of

dryer plugging

We solved a case of D203A polypropylene

reactor housing position repair

We solved a case of split surface in the

turbine block repair

We solved a case of agitation shaft

repair

We solved a case of heat exchanger tube

plate head repair

We solved a case of zirconium alloy spindle

repair

We provided an on-site technical service of

drilling reaming tapping

We optimized manufacturing of localization

accessories- base paper rack reducer

We optimized manufacturing of localization

accessories- 340 pump rotor

We optimized manufacturing of localization

accessories- SDU extruder screw

We optimized manufacturing of localization

accessories-High Speed Pump

We optimized manufacturing of localization

accessories- magnetic pump

We solved a case of reducer repair

We optimized manufacturing of localization

accessories- 920 multi-stage feedwater pump

We solved a case of vertical high speed pump

repair

We optimized manufacturing of localization

accessories- 7000 High Speed pump

We optimized manufacturing of localization

accessories- horizontal High Speed pump HMP211

We provided an on-site technical service of

spraying

We provided an on-site technical service of

supersonic spraying