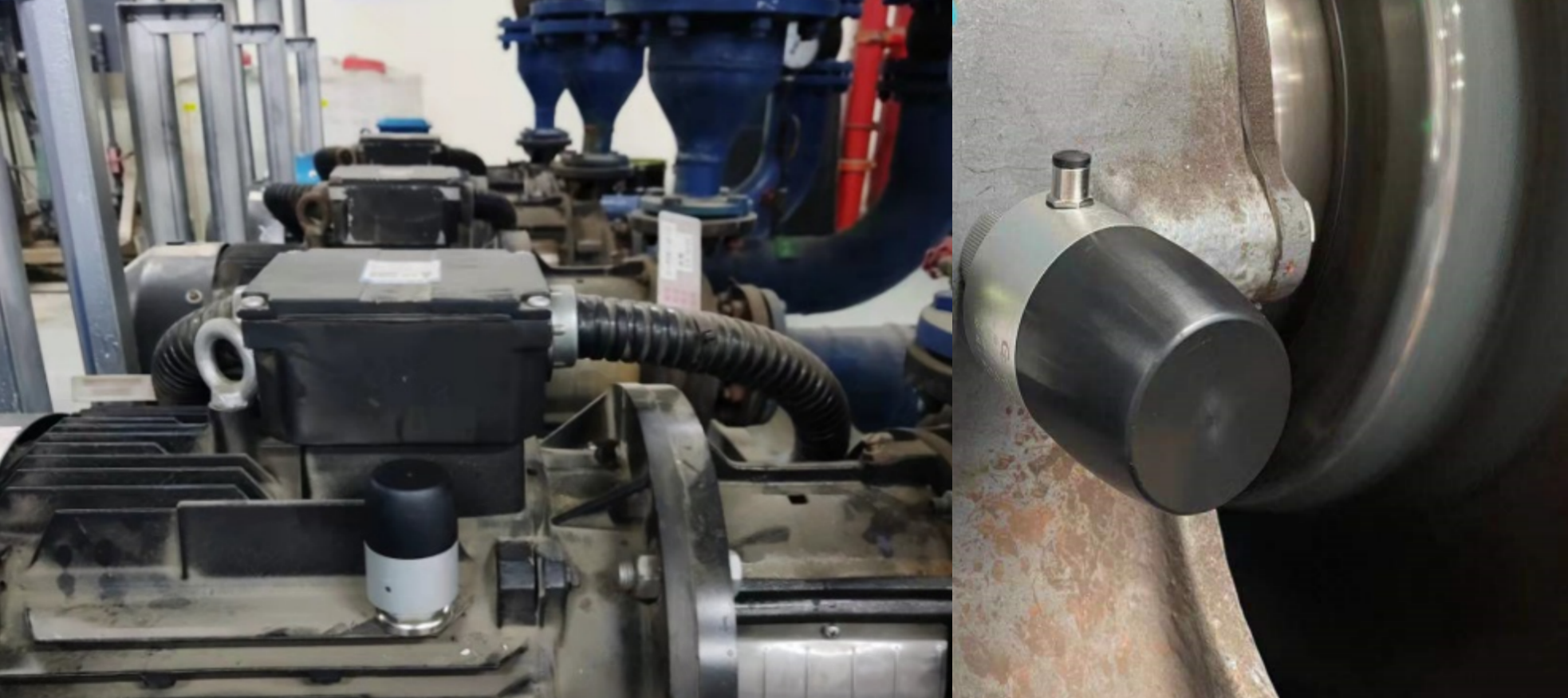

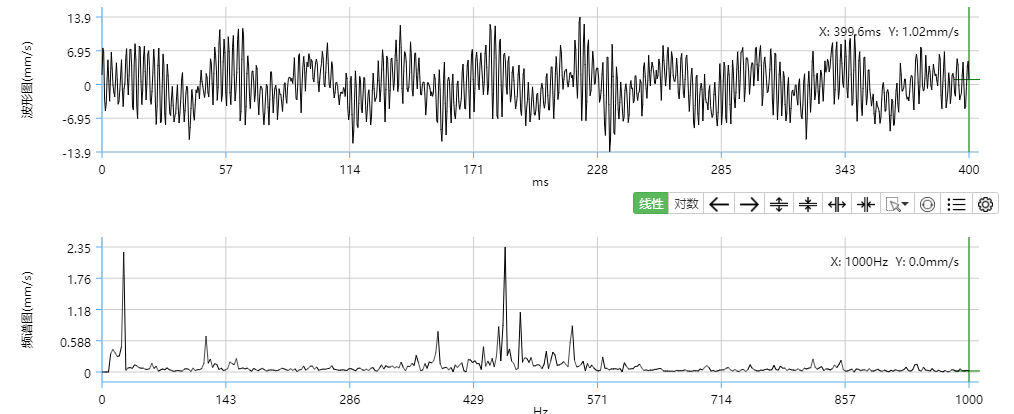

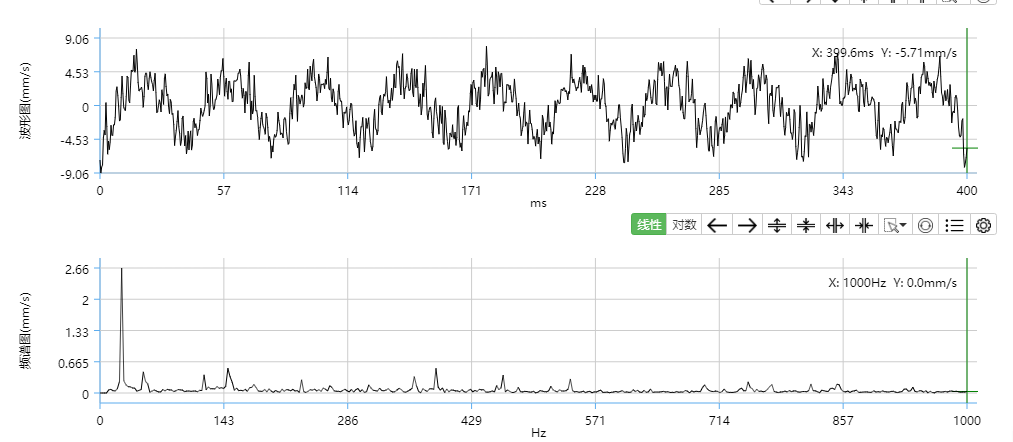

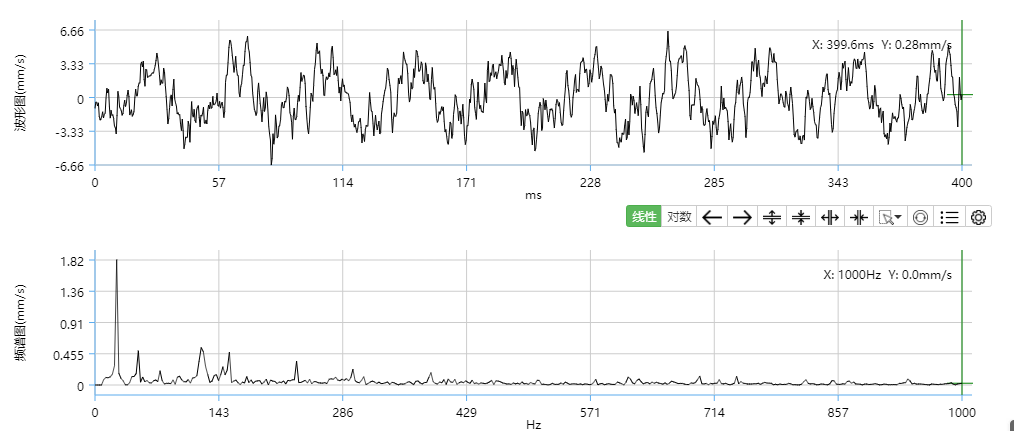

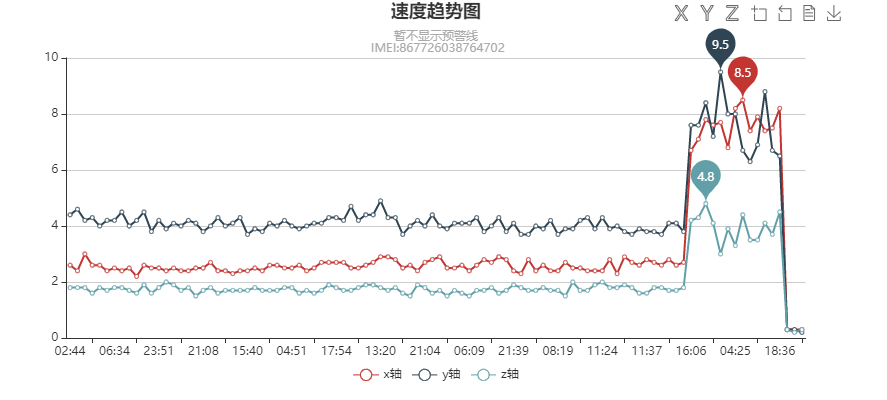

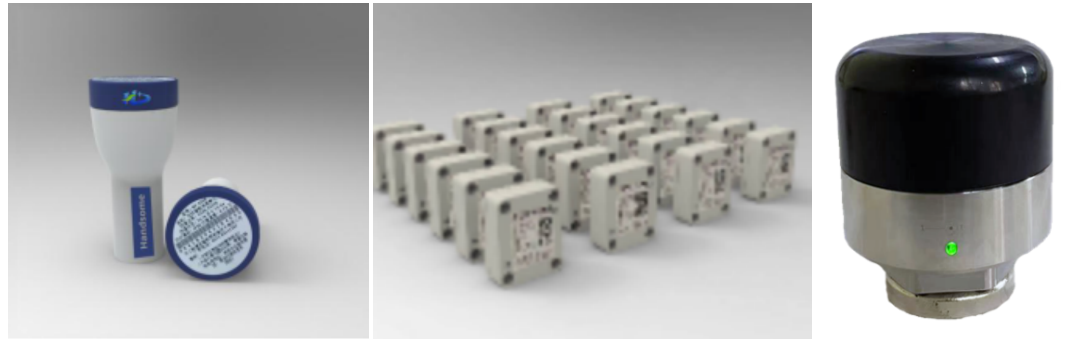

We provide self-developed wireless sensors used on chemical equipment. Transmit data through IoT technology for remote automated equipment monitoring. Integrating mainstream technologies of Internet of Things, cloud computing, big data, artificial intelligence, optimized manufacturing and remanufacturing, it flexibly manages devices for enterprises through the modular architecture of the cloud, understands the operation status of equipment anytime and anywhere, and finds hidden dangers.

Email:

Email:  WhatsApp:

WhatsApp: