AY(s)/AYP Series Centrifugal Oil Pump

- API610(OH2/BB2)

- Max Flow 500M³/H

- Max Head 300m

- Max Operating

Pressure 6.3MPa

- Operating

Temperature -45~+450°C

- Centerline support

pull-back design

- Suitable for a

variety of sealing types of integral heavy

bearings angry frame

- AY(S) ejects in

and out, AYP ends in and out

- The rolling

bearings are lubricated with dilute oil and

equipped with an oil flinging ring, and the

constant position oil cup automatically

controls the oil level

- Standard

non-contact labyrinth seal

- S indicates the

use of double suction impeller

CZ Series Standard Petrochemical Process

Pump

- ISO5199

- ISO2858

- Max Flow 2000M³/H

- Max Head 160m

- Max Operating

Pressure 2.5MPa

- Operating

Temperature -80~+300°C

- Bottom foot

support

- Pull-back design

- Suitable for a

wide range of seal types

- Integral heavy

duty bearing suspension

- Standard

non-contact labyrinth seal

- The rolling

bearings are lubricated with dilute oil, and

the constant position oil cup automatically

controls the oil level

- Standard single

row deep groove ball bearings and double row

angular contact ball bearings or

back-to-back mounting angular contact ball

bearings

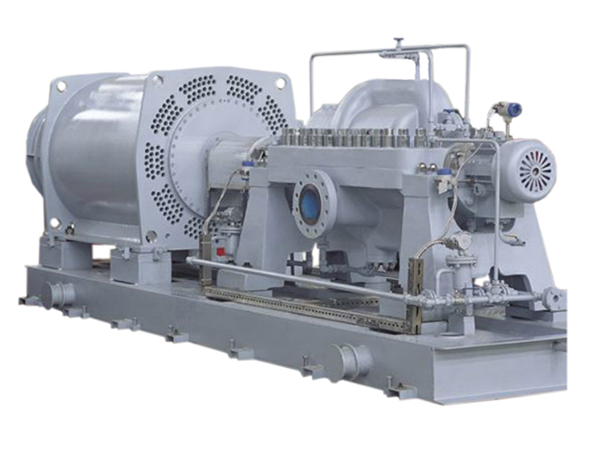

DMS Series Axial Split Multistage Pump

- API610(BB3)

- Max Flow 2400M³/H

- Max Head 2000m

- Max Operating

Pressure 35MPa

- Operating

Temperature -40~+200°C

- The

near-centerline supports axial split double

volute runners

- The impeller is

symmetrically arranged, and the axial force

is self-balancing

- The first stage

impeller can be designed as a single or

double suction structure

- The API682 sealing

chamber is suitable for a wide range of

sealing types for integral heavy bearing

suspensions

- Bearing selection:

Ball radial and thrust plain bearings and

ball thrust bearings ※Plain bearings and

thrust pads

- Standard

non-contact labyrinth seal

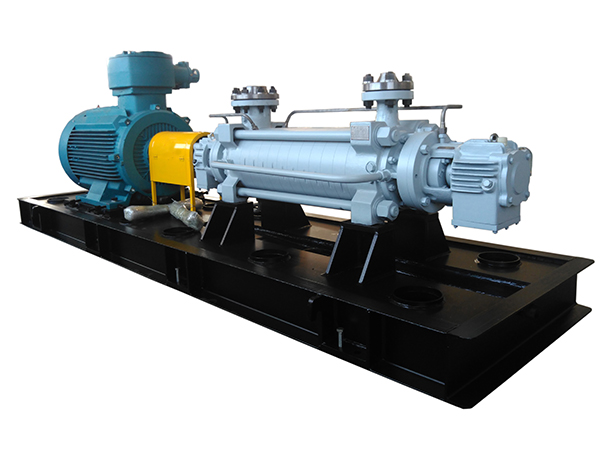

DMS Series Horizontal Multistage Pump

- API610(BB4)

- Max Flow 600M³/H

- Max Head 1200m

- Max Operating

Pressure 15MPa

- Operating

Temperature -80~+180°C

- The foot support

radial sectional first stage impeller has a

very low cavitation margin

- The API682 sealing

chamber is suitable for a variety of sealing

types

- Multi-blade guide

vanes for radial force balancing

- Axial force

balancing uses a balance plate or balance

drum

- The rolling

bearings are lubricated with dilute oil and

equipped with an oil flinging ring, and the

constant position oil cup automatically

controls the oil level

- Standard

non-contact labyrinth seal

- A variety of

flange positions to choose

DSG Series Cartridge Double-Shell Horizontal

Multistage Pump

- API610(BB5)

- Max Flow 1000M³/H

- Max Head 2500m

- Max Operating

Pressure 25MPa

- Operating

Temperature -29~+450°C

- The

near-centerline supports radial

segmentation, segmented inner shell

- The first stage

impeller has a very low cavitation allowance

high head impeller with symmetrical

arrangement The secondary entry 682 sealing

chamber is suitable for radial force balance

of multiple sealing types of multi-blade

guide vanes

- Axial force

balancing uses a balancing drum

- Bearing selection:

ball radial and thrust plain bearings and

ball thrust bearings plain bearings and

thrust pads

- Standard

non-contact labyrinth seal

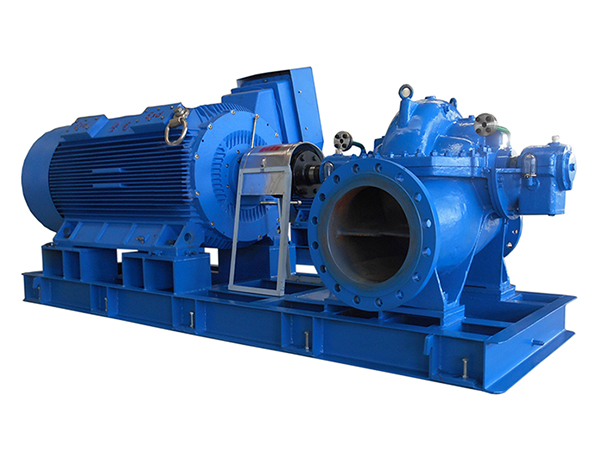

SM Series Axial Split Double Suction

Pump

- API610(BB1)

- Max Flow 10000M³/H

- Max Head 180m

- Max Operating

Pressure 6.3MPa

- Operating

Temperature -20~+160°C

- Foot support

axially split API682 sealing chamber is

suitable for a variety of sealing types

- Integral

heavy-duty bearing suspensions Are standard

drive-end single row cylindrical roller

bearings, non-driven back-to-back mounted

angular contact ball bearings

- The rolling

bearings are lubricated with dilute oil and

equipped with an oil flinging ring, and the

constant position oil cup automatically

controls the oil level

- Standard

non-contact labyrinth sealed double suction

impeller with self-balancing axial forces

- The rotation

direction of the pump can be according to

the user's requirements

- The bearing

suspension is equipped with a water cooling

chamber to cool the oil tank temperature

XB Series Small Flow Petrochemical Process

Pump

- API610(OH2)

- Max Flow

0.8-12.5M³/H

- Max Head 140m

- Max Operating

Pressure 5.0MPa

- Operating

Temperature -45~+450°C

- Centerline support

pull-back design

- Low flow maximum

head design integral heavy duty bearing

suspension

- The API682 sealing

chamber is suitable for a variety of sealing

types

- Standard single

row cylindrical roller bearings and

back-to-back mounting angular contact ball

bearings

- Special bearing

layouts for high suction pressures

- Rolling bearings

are lubricated with dilute oil, and the

constant position oil cup automatically

controls the oil level

- Standard

non-contact labyrinth seal

ZA/ZAO Series Petrochemical Process

Pump

- API610(OH1)

- Max Flow 2600M³/H

- Max Head 250m

- Max Operating

Pressure 2.5MPa

- Operating

Temperature -80~+250°C

- Foot support,

pull-back design

- Integral heavy

duty bearing suspension

- Export DN80 or

above adopts double worm type design

- The API682 sealing

chamber is suitable for a variety of sealing

types

- Standard single

row cylindrical roller bearings and

back-to-back mounting angular contact ball

bearings

- Rolling bearings

are lubricated with dilute oil, and the

constant position oil cup automatically

controls the oil level

- The standard

non-contact labyrinth seal ZAO uses an open

impeller

ZE/ZEO Series Petrochemical Process

Pump

- API610(OH2)

- Max Flow 2600M³/H

- Max Head 250m

- Max Operating

Pressure 2.5MPa

- Operating

Temperature -80~+450°C

- Centerline support

pull-back design

- Outlet DN80 and

above adopts a double volute design

- The API682 sealing

chamber is suitable for a variety of sealing

types

- Integral

heavy-duty bearing suspensions are used for

special bearing layouts with high suction

pressures

- Standard single

row cylindrical roller bearings and

back-to-back mounting angular contact ball

bearings

- The rolling

bearings are lubricated with dilute oil, and

the constant position oil cup automatically

controls the oil level

- The standard

non-contact labyrinth seal ZEO uses an open

impeller

Email:

Email:  WhatsApp:

WhatsApp: