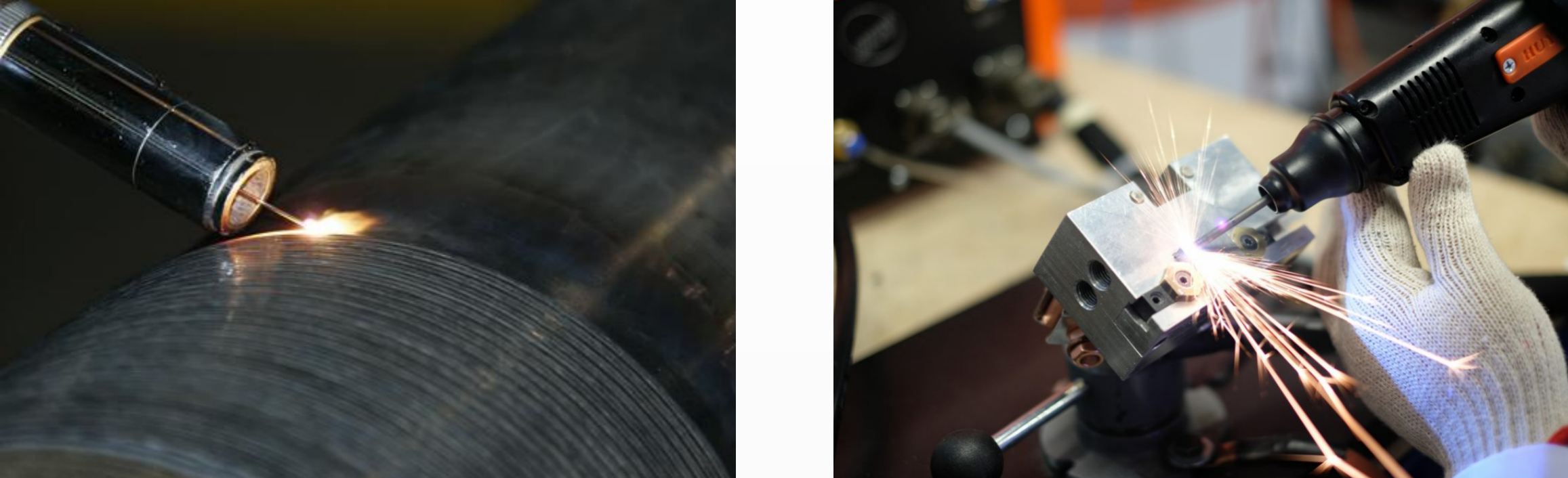

Micro-arc spark deposition is a pulse arc micro-welding process, which is a capacitor discharge, micro-arc fusion welding method, using controlled energy discharge to form a short-term electrical pulse to produce metallurgical combination of surface modification or forming. The material to be deposited is made of a rod as a positive electrode and the workpiece as a negative electrode. Under the action of high pulse energy flow, the metallurgical reaction between the cathode and the micro-arc spark occurs through the ion arc, and the electrode rod is transferred to the contact area with the substrate at self-consumption. Compared with laser surface treatment, micro-arc spark surface treatment has less thermal impact on the matrix, basically does not cause deformation of the workpiece and the microstructure of the matrix material changes, many materials that cannot be melted with conventional fusion welding methods can often be melt welded with micro-arc sparks.

- Pulse arc microscopy

- Capacitor discharge, micro - arc fusion welding

- Metallurgical bonding

- The heat effect is less

- It will not cause workpiece deformation and matrix material structure change

- Micro - arc spark fusion welding

Email:

Email:  WhatsApp:

WhatsApp: