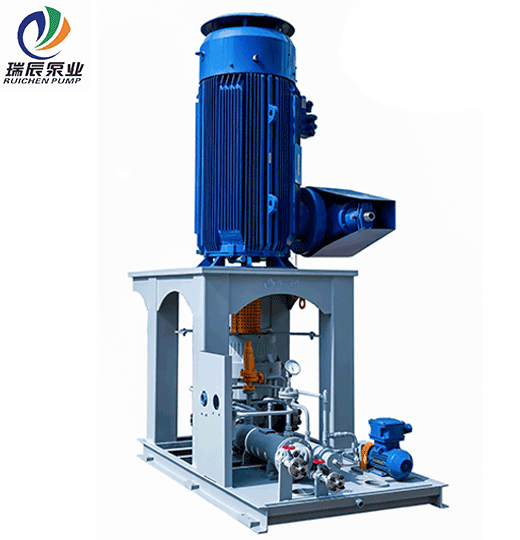

GSB-XXX series pump is a single-stage, single suction, cantilever, vertical High Speed pump, mainly composed of motor, growth box, pump body, lubrication system and base. The growth rate of the growth box is divided into a first-level growth rate and a second-level growth rate according to different working conditions and configuration requirements. The inlet and outlet flanges of this series of High Speed pumps are symmetrically arranged on the same horizontal center line, with a compact and beautiful appearance and a small footprint.

- Max Flow 250M³/H

- Max Head 2180 m

- Max Suction Pressure 6.8MPa

- Max Operating Pressure 20.0MPa

- Max Motor Power 355kW

- Operating Temperature -130~+340°C

- RPM 4950-28000

- Gearbox Construction Form Second-Level Growth Speed

High-precision, highly reliable growth box drive system

The box and gear shaft are the key components of the High Speed pump, the heat treatment process is complex, and the processing and coordination accuracy are high. After years of exploration, our company has formulated a set of perfect processing technology, strictly control the chemical composition and heat treatment of castings, and then carry out multiple stabilization treatments after initial processing to ensure that the box meets the requirements of high strength and high stability. Each part is rigorously inspected and documented after processing to achieve traceability of the quality process.

Plain bearings with high load and stability

We have independently developed a variety of series of plain bearings, which can be flexibly assembled according to different working conditions. In view of the specific working conditions such as high inlet pressure and high power, a variety of tilting tile bearings integrating axial, radial and axial and radial have been successfully developed, which improves the stability and reliability of High Speed pump products and expands the application field of High Speed pumps.

High-efficiency, high-performance hydraulic component design

The hydraulic components of the High Speed pump are mainly composed of induction wheels, impellers, diffusers, housings, etc. With the help of numbers Value simulation software to optimize hydraulic models for High Speed pumps.

Flexible and versatile sealing styles

The unit is equipped with a sealing form and flushing scheme in accordance with API standards to meet the needs of various working conditions of users.

US 60 Hz

- Heads to 6,300 ft

- Flows to 400 gpm

- Standards API 610 OH6

- Maximum Motor Power 200 HP

- Temperature Range -200 to 650°F

- Maximum Case Working Pressure 1,260 psi

- Maximum Suction Pressure 1,000 psi

- Differential Head 6,300 ft

- Maximum Viscosity 750 cp

- Solids Range 0.015″, 400 microns

- Mounting Configuration Vertical, Horizontal

- Seal Configurations Single, Double, Tandem

- Inducer Yes

- Flanges ANSI 600# RF, 900# RF Optional

- Suction and Discharge 3″ x 2″

- API Plans 11, 12, 13, 21, 23, 31, 32, 41, 52, 53, 54, 61, 62, J

Metric 50 Hz

- Heads to 1,348 m

- Flows to 73 m3/hr

- Standards API 610

- Maximum Motor Power 150 kW

- Temperature Range -130 to 340°C

- Maximum Case Working Pressure 155 kg/cm2

- Maximum Suction Pressure 71 kg/cm²

- Differential Head 1,921 m

- Maximum Viscosity 750 cp

- Solids Range 0.381mm, 400 microns

- Mounting Configuration Vertical, Horizontal

- Seal Configurations Single, Double, Tandem

- Inducer Yes

- Flanges ANSI 600# RF, 900# RF Optional

- Suction and Discharge 3″ x 2″

- API Plans 11, 12, 13, 21, 23, 31, 32, 41, 52, 53, 54, 61, 62, J

Email:

Email:  WhatsApp:

WhatsApp: